- General Properies

- Temperature and Pressure Relationship

- Thermal Conductivity

- Linear Expansion Coefficient

- Freezing and Thawing Resistance

General Properties

PB resin is a polymer made by synthesizing butene-1 and is a polyolefin-based composite with high crystallinity.

| Properties | Unit | Test Method | Property Limit | |

|---|---|---|---|---|

| Physical Properties | Importance | - | ASTM D1505 | 0.937 |

| Hardness | D scale | ASTM D2240 | D60 | |

| Absorption Rate | mg/㎠ | JIS K7209 | 0.01 or below | |

| Mechanical Properties | Tensile Yield Strength | kgf/㎠ | ASTM D638 | 170 |

| Tensile Breaking Strength | kgf/㎠ | ASTM D638 | 340 | |

| Tensile Fracture Stretching | % | - | 250 | |

| Elastic Modulus | kgf/㎠ | ASTM D638 | 2.700 | |

| Possion | - | - | 0.38 | |

| Impact Strength | kgf/㎠ | JIS K7110 | 45 | |

| Thermostatic Properties | Creep | ℃-1 | D696 | 1.3 x 10-4 |

| Specific Heat | cal/g℃ | - | 0.5 | |

| Thermal Conductivity | kcal/m.hr.℃ | C177 | 0.33 | |

| Melting Point | ℃ | DTA | 124℃~126℃ | |

| Brittle Temperature | ℃ | JIS K7216 | -18℃ | |

| Electrostatic Properties | Volume Resistivity | Ω.com | ASTM D257 | 1017 or above |

| Withstand Voltage | kv/mm | ASTM D149 | 38 | |

General Properties

PB resin is a polymer made by synthesizing butene-1 and is a polyolefin-based composite with high crystallinity.

| Working Pressure (Kg/㎠) | |||||

|---|---|---|---|---|---|

| 20℃(50years) | 40℃(50years) | 60℃(50years) | 70℃(50years) | 80℃(25years) | 90℃(10years) |

| 16.32 | 13.97 | 10.71 | 8.98 | 7.55 | 5.00 |

Thermal Conductivity

PB pipes have the advantages of less thermal conductivity and less heat loss than metal pipes. Therefore,

hot water flows more efficiently than metal pipes. However, for long-distance piping and piping that minimizes heat loss, use a thermal insulation material.

| Material of Pipies | Thermal Conductivity Coefficient ㎉/m.hr.℃ | The Ratio of PB Tube to 1 |

|---|---|---|

| PB Pipies | 0.33 | 1 |

| Stainless Pipies | 14 | 7 |

| Steel Pipes | 50 | 250 |

| Aluminum Pipes | 180 | 900 |

| Copper Pipies | 340 | 1.700 |

Linear Expansion Coefficient

Since the thermal expansion and contraction force of the PB pipe is about 1/60 of that of the metal piping material,

the PB pipe of the drowned pipe can hold the expansion and contraction of the pipe enough for the friction of soil or concrete

when it is buried in concrete. For this reason, thermal expansion and contraction of the PB pipe is not usually considered.

| Materials | Linear Expansion Coefficient (℃-¹) | Tensile Elastic Ratio (kgf/㎠) |

|---|---|---|

| PB Pipies | 1.3~1.5x10-4 | 4,000 |

| Stainless Pipies | 0.09~0.1x10-4 | 2,800,000 |

| Steel Pipes | 0.1~0.11x10-4 | 2,100,000 |

| Copper Pipies | 0.17~0.18x10-4 | 2,100,000 |

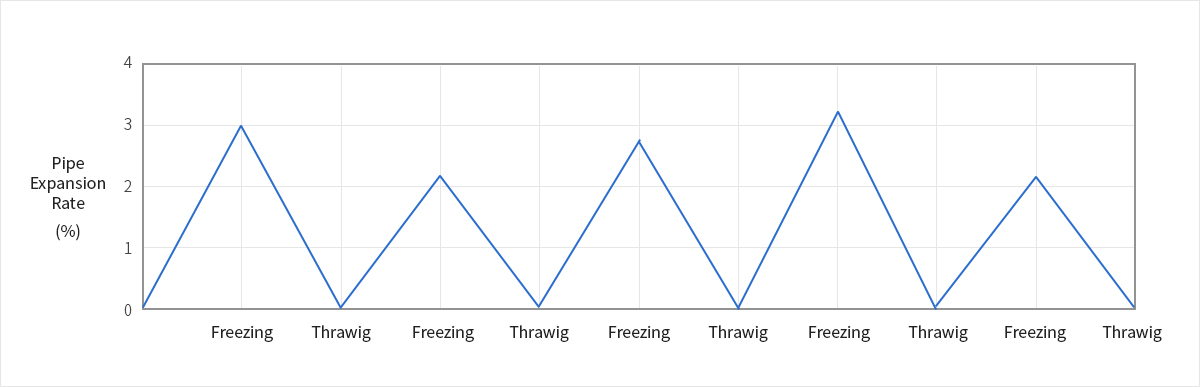

Freezing and thawing resistance

The graph below shows the results of repeated tests of freezing and thawing PB pipes.

The test method is to fill the test pipe with water and repeat the freezing and thawing cycles of [-20 ℃ / 16hr ↔ 23 ℃ / 8hr].

PB pipes are not frozen in the test results. This indicates that the PB pipe is flexible enough to absorb the volumetric expansion of water by freezing.

However, this test uses a short tube, so you should not apply this result to actual piping. For example, if the entire length of a long pipe is frozen,

there is no problem if the entire pipe is frozen at the same time. However, if the volume increase due to freezing is concentrated on a part of the pipe,

it may be damaged. Therefore, in case of piping where there is a risk of freezing of any piping material, please take anti-freezing measures such as using antifreeze,

removing water or keeping warm.